The quality of the raw materials entering the production processes is an essential aspect carried out in a careful way. The materials have to be the first-class quality to guarantee the best outcomes possible. That is why we cooperate with verified and reliable suppliers from all over Europe.

The majority of our production starts right at this point. To fulfill the maximum capacity of these machines production must be planned in the most efficient way. We are equipped with lasers that are working in a very accurate and quick way and allow us to cut out even a very complicated composition.

Excellent and stable bending results of the metal parts are reached by our trained and skilled employees who are continually educated to operate various bending machines in our machinery fleet. Planning the production with such diverse options of bending machines assures the highest speed and efficiency of our projects.

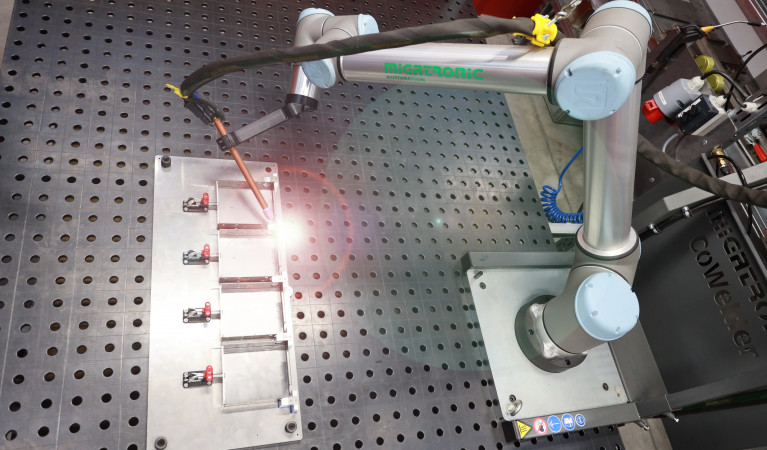

Undoubtedly, one of the most difficult operational skills which requires knowledge, experience and a bit of a talent when it comes to a manual welding. Welders are trained on regular basis to be able to perform top quality welding of the joints. Technologies TIG and MIG are used for both welding manually or automatically. Swiss Form expects to equip the production with an automated laser welder that will raise up the quality a bit further in a very near future.

We have experience with robotic welding since 2015 in cooperation with ABB and Migatronic.

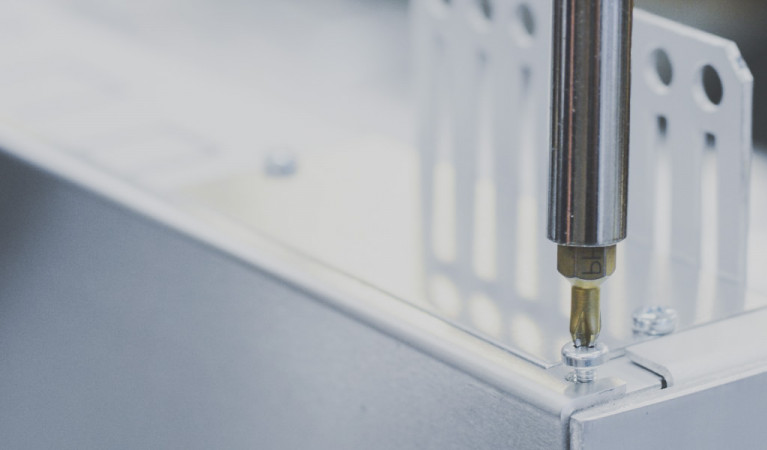

In 2020, we opened a new CNC machining facility that replaces work on conventional machines.

Since 2020 we operate our own powder coating plant in a two-shift operation.

We have more than 25 years of experience with screen printing technology. We use both manual and advanced machine technology.

Our production capacity allows us to provide our customers with fully or partly assemblies of the products. Employees working on the set up of the assemblies are experienced with simple but also complicated compositions including electrotechnical parts, screen printing and special packaging for the end customer

Including all the described technologies which are main activities we also offer additional services to adjust the outcomes such as powder coating; wet painting; electrolytic zinc-coating; anodising and chrome plating of aluminium and more. If there is a technology that we cannot provide one of our suppliers certainly will.